It was in the year 1905 that Joseph Bamford relinquished the management of the Lichfield Agricultural Company and returned to Uttoxeter. In the same year his two sons, Cyril and Gerald, joined him at the Uttoxeter works.

George Samways, later to become sales manager of the parent company and one of the best-known figures in the agricultural machinery industry succeeded him as manager at Lichfield.

On returning to Uttoxeter, Joseph became involved the design and development of new haymaking machinery and in 1910 invented a swath turner. The machine proved to be extremely successful and had a large sale, but was the subject of a legal action by Blackstone’s who manufactured a similar machine and contended that Bamfords machine was an infringement of their patents. Bamfords however were successful in this action.

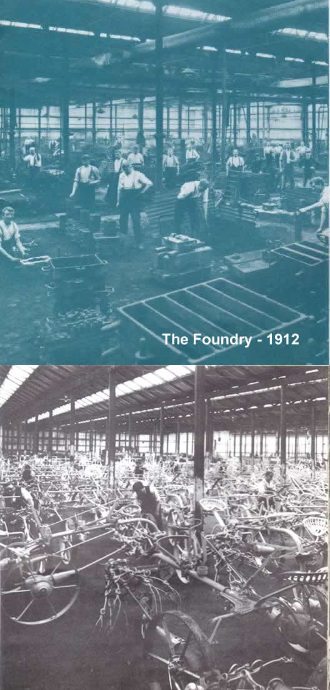

Further development at the works took place in 1912 with the erection of a new foundry at a cost of £70,000. The expansion of the works buildings was a continuous process undertaken by the employees during slack periods of the year, such as autumn. Whilst the structures appeared somewhat crude with cast-iron columns, wood and corrugated iron roofs, this form of construction was deliberate in that they were rated as temporary structures.

During the period of 1912 — 1918 further buildings were erected in the Hockley area as they were needed and it was at this time that part of the factory, now the West works, became known as the Klondyke. This area of the works was not used in the winter due to lack of heating, but in the early spring the workers moved over to this part of the factory to build up rakes and haymaking machinery. Sales of this type of machinery represented a large portion of the company’s turnover and so this move each spring became known as “The Gold Rush” to the Klondyke.

Records show that the factory opened at 6.00 a.m. At 8.00 a.m. there was one half-hour for breakfast, when the local children would call and bring breakfast for their fathers. Work continued 8.30 a.m. until 5.30 p.m. with a break of one hour for lunch.

Timekeeping was strict — on arrival, employees clocking in had to transfer a brass tally from one board to another. Workers who were late were fined 1 penny, late again the following day meant a fine of twopence and, if late again on the third day, the brass tally was removed and the employee went home minus the day’s pay to return the following day. It was at this time a Uttoxeter landmark appeared at the works with the building of a large chimney for the main Lancashire steam boilers that provided steam power and heating for the works. The boilers were, in fact extremely advanced for their time incorporating automatic stoking. It is understood that the chimney became quite an attraction during its construction, with baskets being pulled to the top for a fee of one penny per person, allowing people to view the town. The landmark disappeared in 1966 when the chimney was demolished.